Transforming carbon-based waste into high-purity hydrogen without electrolysis or fossil fuels.

White Hydrogen is naturally occurring hydrogen sometimes found in geological formations deep within the earth’s crust. While the concept of extracting geological hydrogen is promising, practical and commercial-scale recovery is still years away.

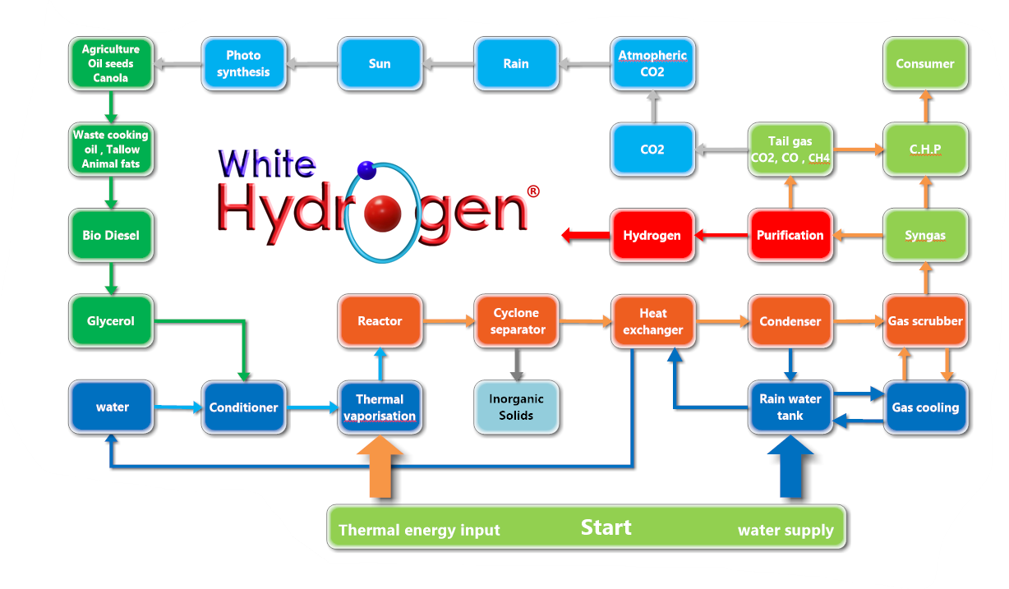

Delafield’s White Hydrogen Platform generates clean hydrogen above ground, using advanced thermal processing of carbon-based waste — such as crude or semi-refined glycerol, a waste byproduct of biodiesel production. This process requires no electrolysis, fossil fuels, or carbon emissions.

Developed by Delafield Pty Ltd, White Hydrogen and H2-XERONOX® is a proprietary, patent-pending platform for decentralised hydrogen production from waste-derived feedstocks. It operates without catalysts or purified water, making it modular, low-CAPEX, and ideal for local deployment.

Carbon-based waste (e.g., crude glycerol enters the H2-XERONOX® thermochemical reactor.

Thermal processing with steam breaks molecular bonds to produce hydrogen-rich syngas.

Syngas passes through a Pressure Swing Adsorption (PSA) system.

PSA separates gases to produce 99.999% pure hydrogen.

Converts carbon-based waste into hydrogen-rich syngas.

Extracts 99.999% pure hydrogen.

Compact, scalable, and deployable in a 20ft container for local applications.

Advanced controls ensure efficient and reliable hydrogen production.

The pilot plant produces up to 100 kg of hydrogen per day. In test runs, semi-refined and crude glycerol were converted to hydrogen-rich syngas with over 80% hydrogen concentration.

After PSA purification, the system delivers 99.999% pure hydrogen, ready for fuel cells, industrial heating, or energy storage.

H2-XERONOX® offers greater energy efficiency than traditional electrolysis by utilising carbon-based waste as feedstock, significantly reducing energy consumption and lowering production costs through its carbon-negative potential.

H2-XERONOX® delivers clean, affordable hydrogen from waste—driving real-world impact in energy, industry, and the environment.