Over 2.24 billion tonnes of municipal waste are generated globally each year, with significant contributions from agricultural byproducts and non-recyclable plastics.

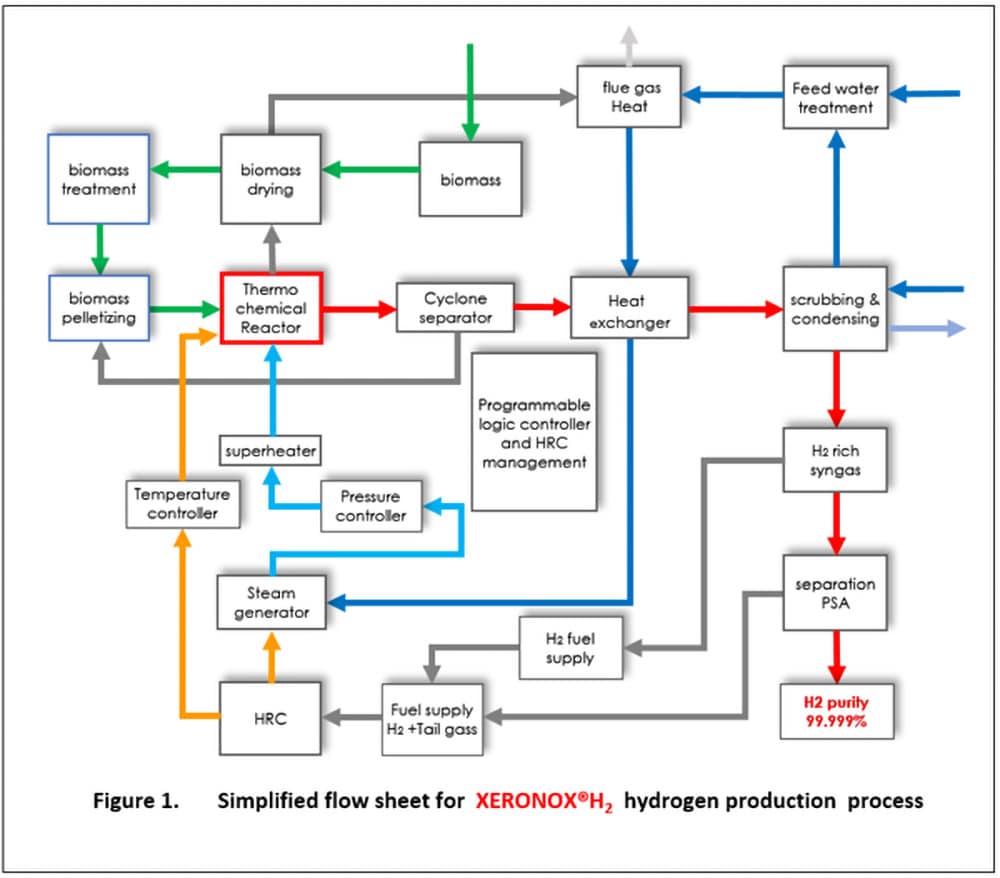

White Hydrogen’s H2-XERONOX® technology converts these waste streams into high-purity hydrogen, reducing landfill dependency and enabling a circular economy.